We Don’t Just Design for AM, We Design Possibility.

Metamorphic delivers purposeful, simulation-led design. Not templates, but tailored geometries built to solve real-world problems in demanding sectors.

Metamorphic doesn’t just design for additive, we engineer with purpose. We work with frontier industries to unlock performance that traditional methods can’t reach, delivering solutions where geometry is born from function, not just manufacturability. As an early-stage innovation partner, we collaborate closely with clients through deep technical engagement and co-engineering cycles grounded in simulation, material behaviour, and production realities.

From first principles to final validation, every step is shaped by intent, insight, and iteration. We challenge the illusion that AM success can be automated, and instead deliver geometries that are meaningful, manufacturable, and measurable. Because at Metamorphic, we don’t settle for what’s printable. We ask, “what’s the best this part can be?”

We’re not a software vendor.

We’re engineers, designers, researchers and coders who build the computational design tools we need to solve problems others can’t.

Our Approach

Metamorphic partners with innovators who are serious about doing AM the right way. We offer flexible, high-value design and R&D support that helps you move beyond additive curiosity and into real, scalable impact. Whether you're starting with fundamental research or pushing toward production and even considering mass production, we embed engineering intent into every phase, transforming early ideas into functionally optimised, manufacturable outcomes.

Our workflows don’t just accelerate breakthroughs; they reduce risk, expose opportunity, and build confidence in AM as a long-term strategy. From feasibility and proof-of-concept to simulation-led validation, we guide you through complexity with clarity, ensuring that geometry, material, and process decisions are grounded in purpose, not assumption. And because we believe in empowering our clients, you retain ownership of your IP and outputs at every stage.

Whether you're a start-up chasing first-mover advantage, an academic group applying AM to novel research, or an established manufacturer rethinking your product architecture, Metamorphic is here to help you design with intent and build with confidence.

Our Team

-

Dr Manolis Papastavrou

PhD, MEng(Hons), MSc(Hons)

Computational Design Lead, Co-founder and Director.

Manolis's role focuses on the development of advanced computational design workflows that harness geometric complexity and automate the design of components produced through additive manufacturing.

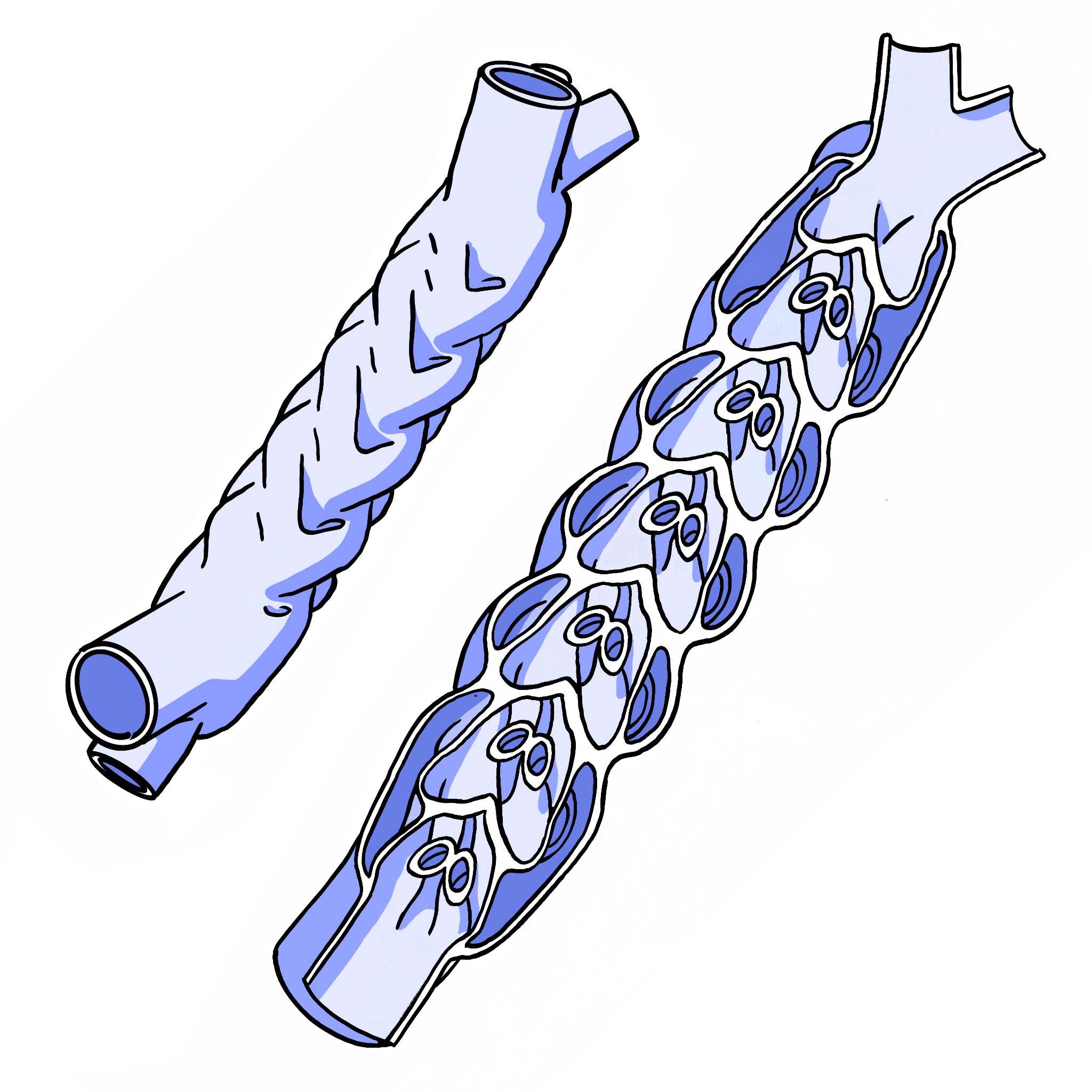

With a background in Chemical Engineering and Product Design, he started his career in Additive Manufacturing (AM) with a PhD on 3D printed synthetic bone substitutes. He has since worked as a Research Engineer developing and optimising AM processes with an emphasis on powder bed fusion and jetting. Throughout this journey, design has always been at the core of his engineering practice; he has been involved in projects that range from conceptual footwear and medical devices to scientific instrumentation. Combining computational design with 3D printing fuels his interest for bio-inspired design.

-

Dr Laurence Coles

PhD, CEng, MEng (Hons)

Mechanical Design Lead, Co-founder and Director.

Laurence’s role focuses on breaking the mould of conventional engineering design through his creative approach to problem-solving and a desire to learn from and collaborate with people from outside of his field of expertise. His foundations in classical engineering and simulation provide insights into the performance of Metamorphic’s pioneering designs.

With a background in Mechanical Engineering and a PhD in ballistics, blast, and mechanics of materials. He started his career in Additive Manufacturing as a research engineer, leading design projects and supporting clients with their exploration of AM across various high-tech industries, including quantum technologies, medical devices, healthcare, and oil and gas.