The Future of DfAM isn’t

Mindless Automation

— It’s Intelligent Design.

You think you’ve optimised your design for additive manufacturing?

Think again. Most designs only scratch the surface of AM’s true potential.

Metamorphic unlocks the remaining potential.

Unlock Your AM Potential

What we believe

Too many teams mistake “printable” for “optimised.”

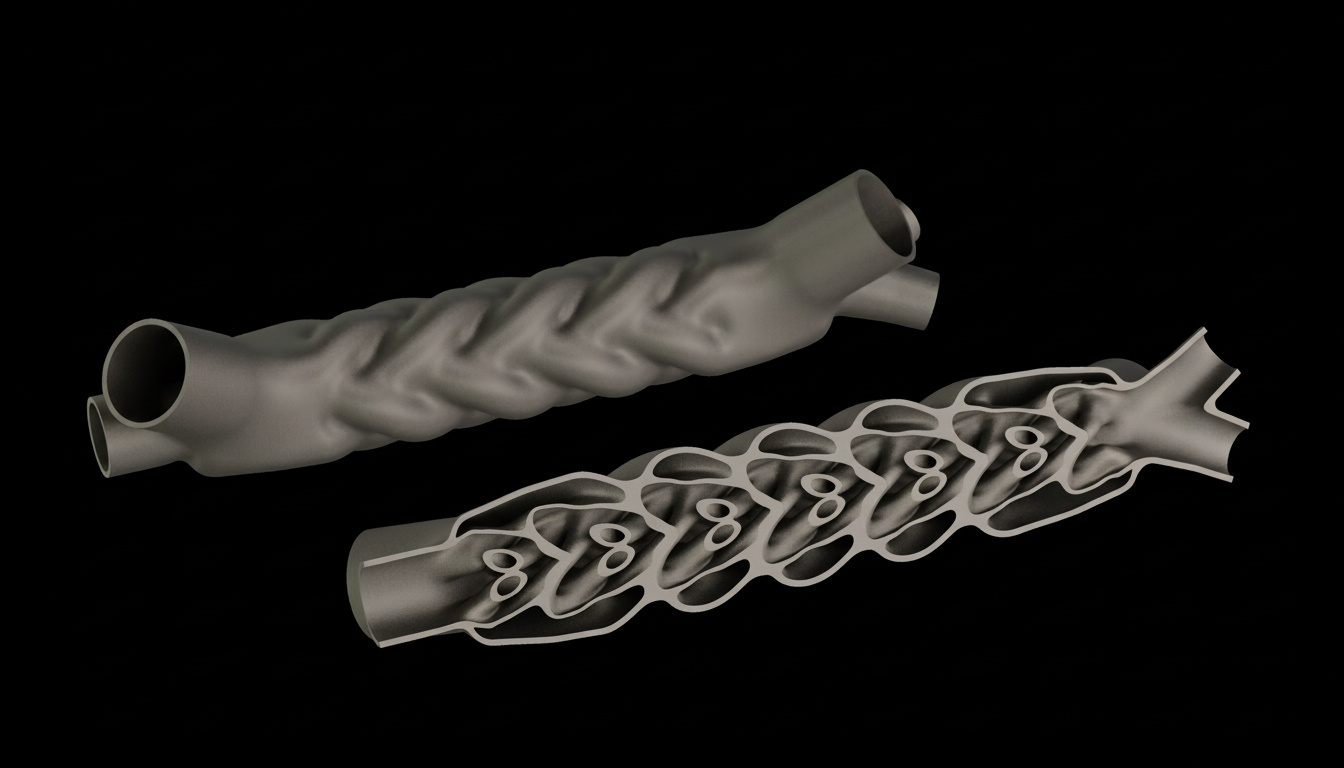

At Metamorphic, we know that’s where innovation stalls. Most Design for Additive Manufacturing (DfAM) today is adaptation, not transformation. It’s tweaking legacy geometries or relying on default settings in latticing tools and calling it progress.

The result? Predictable shapes. Safe choices. Missed opportunities.

We’re here to rewrite that script.

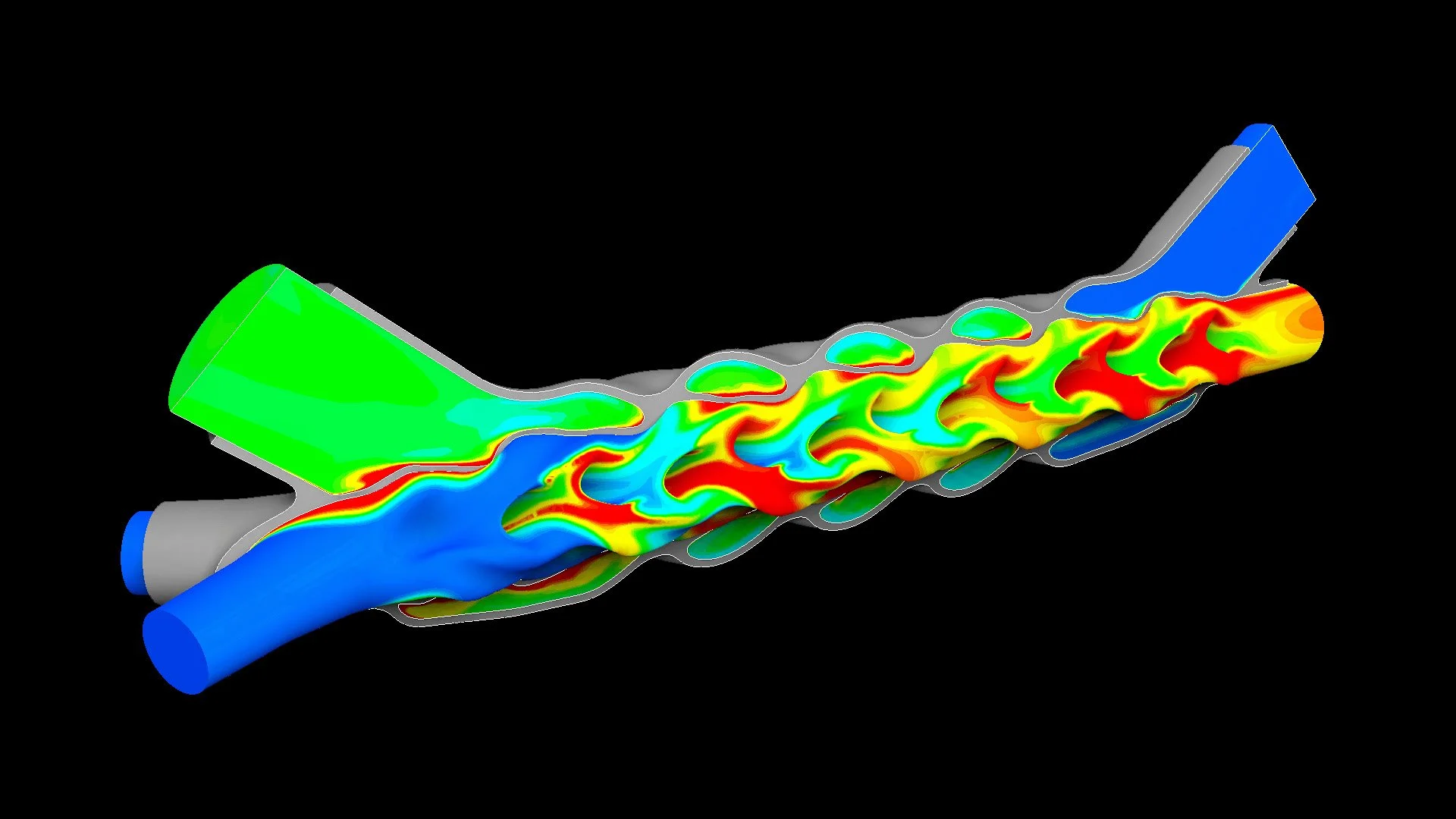

True DfAM begins with purpose, not presets. It means designing with intent, understanding what a part needs to do, not just what the printer can handle. Our work doesn’t stop at simulation or support reduction.

We ask, “What’s the best version of this part, functionally, structurally, and at scale?”

This isn’t about complexity for complexity’s sake. It’s about performance you can prove, manufacturability you can trust, and innovation you can scale.

We don’t chase what’s printable. We engineer what’s possible.

What We Do

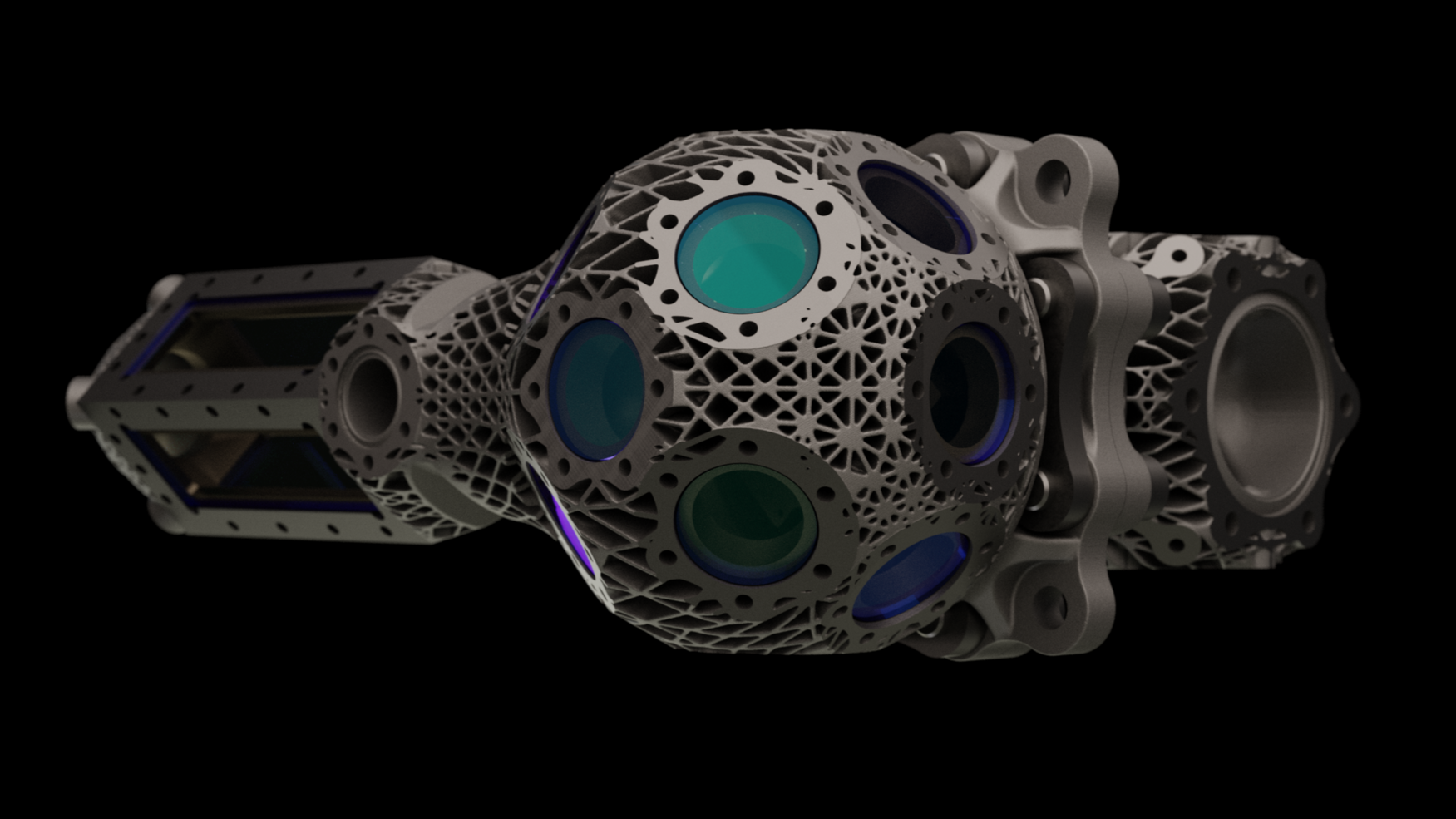

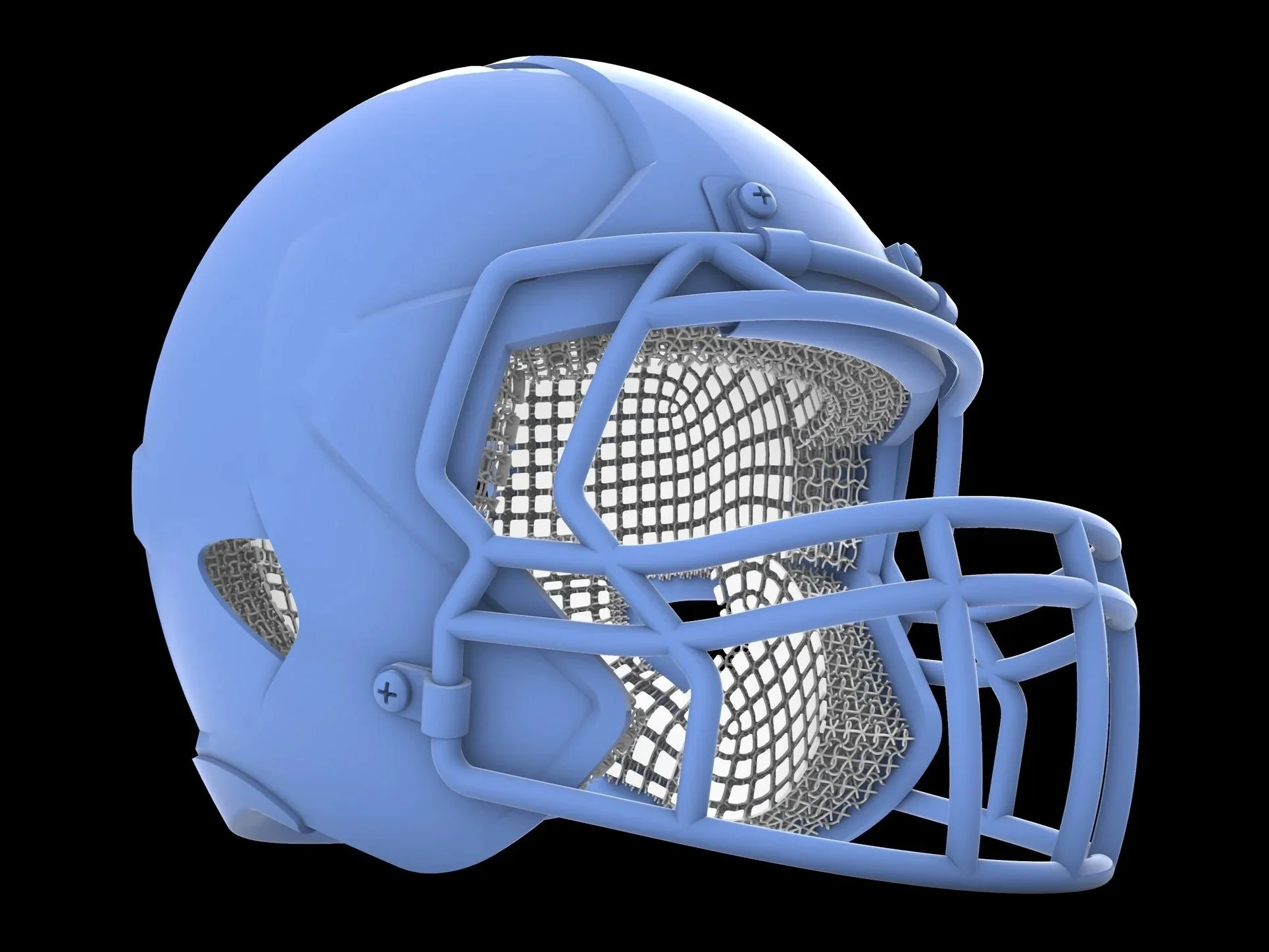

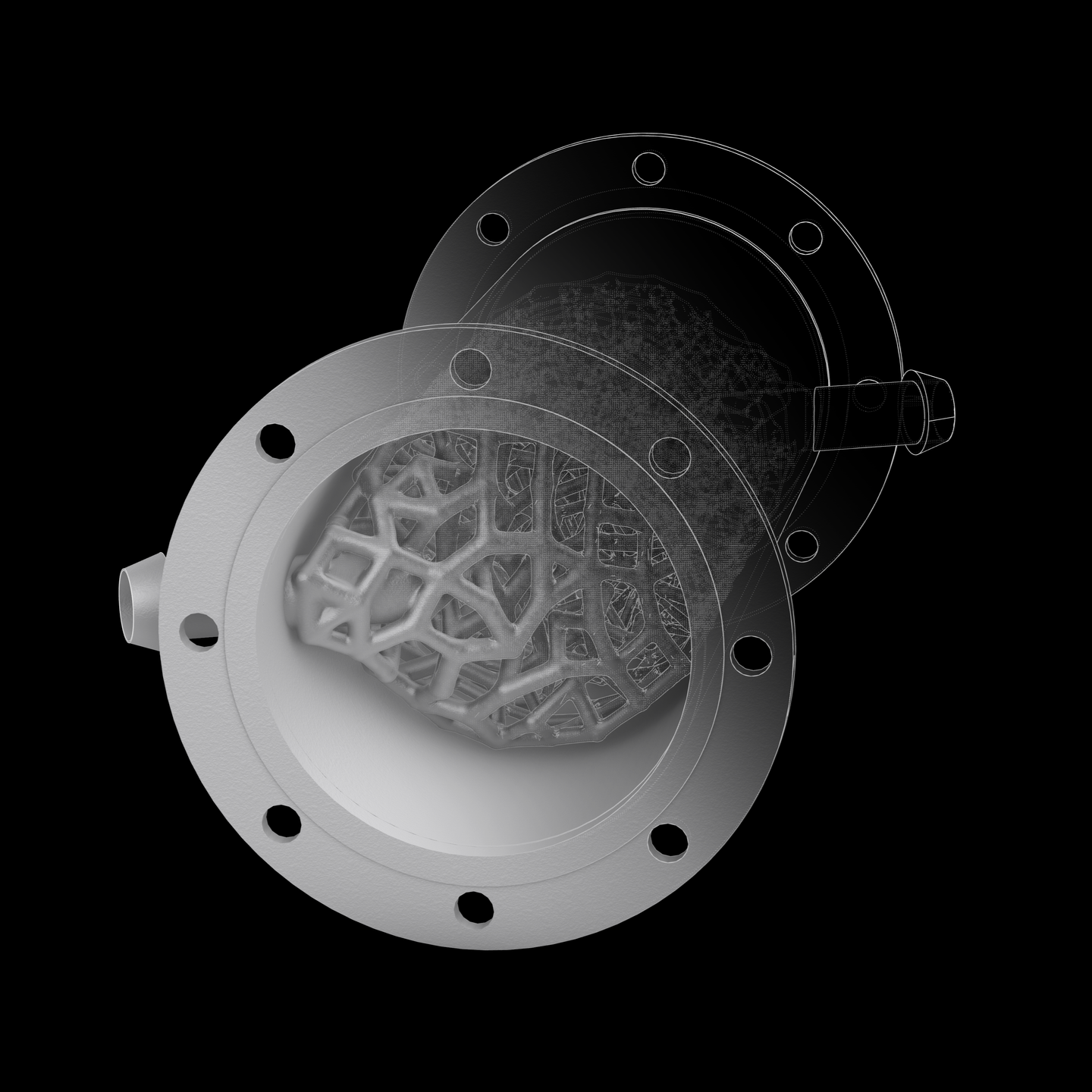

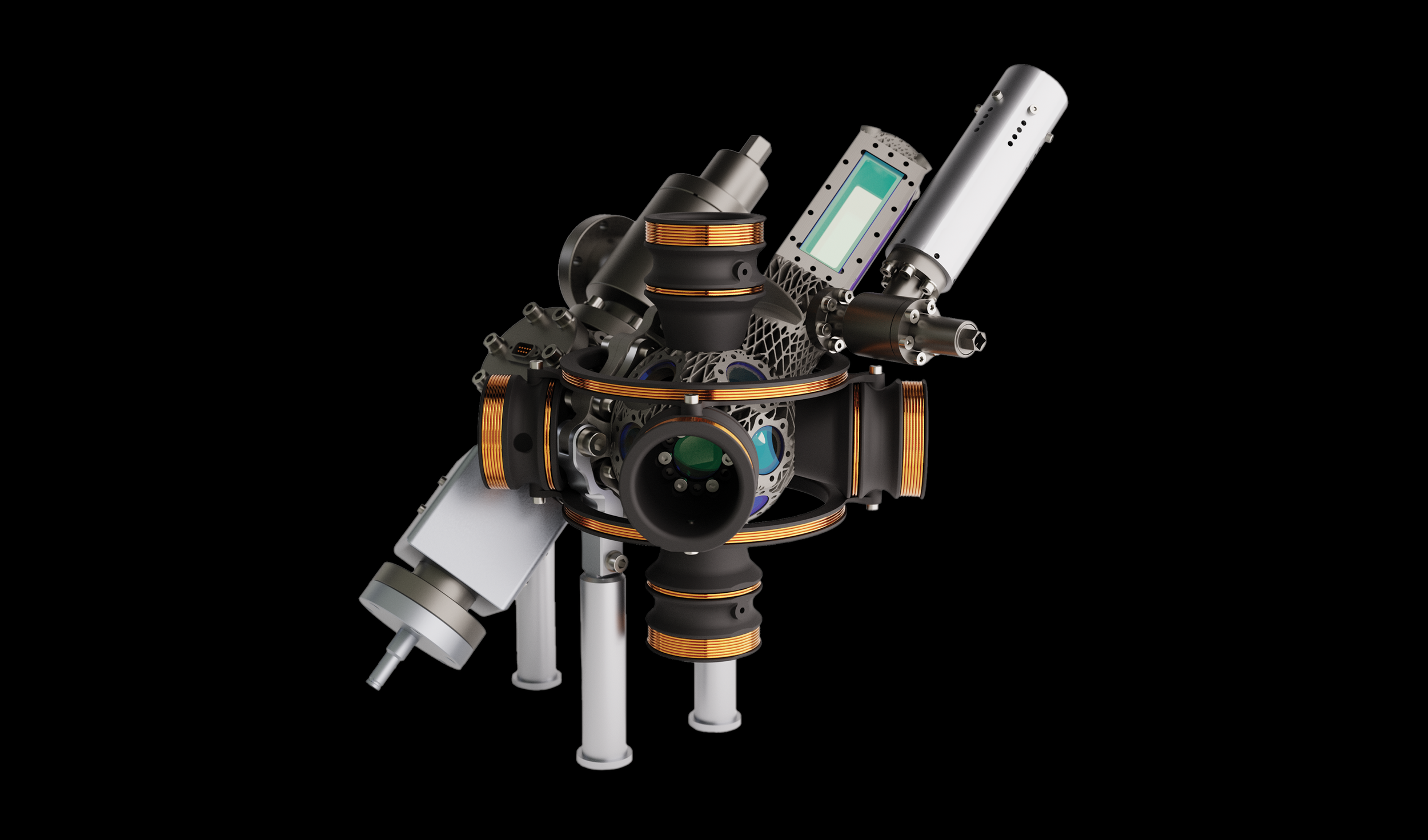

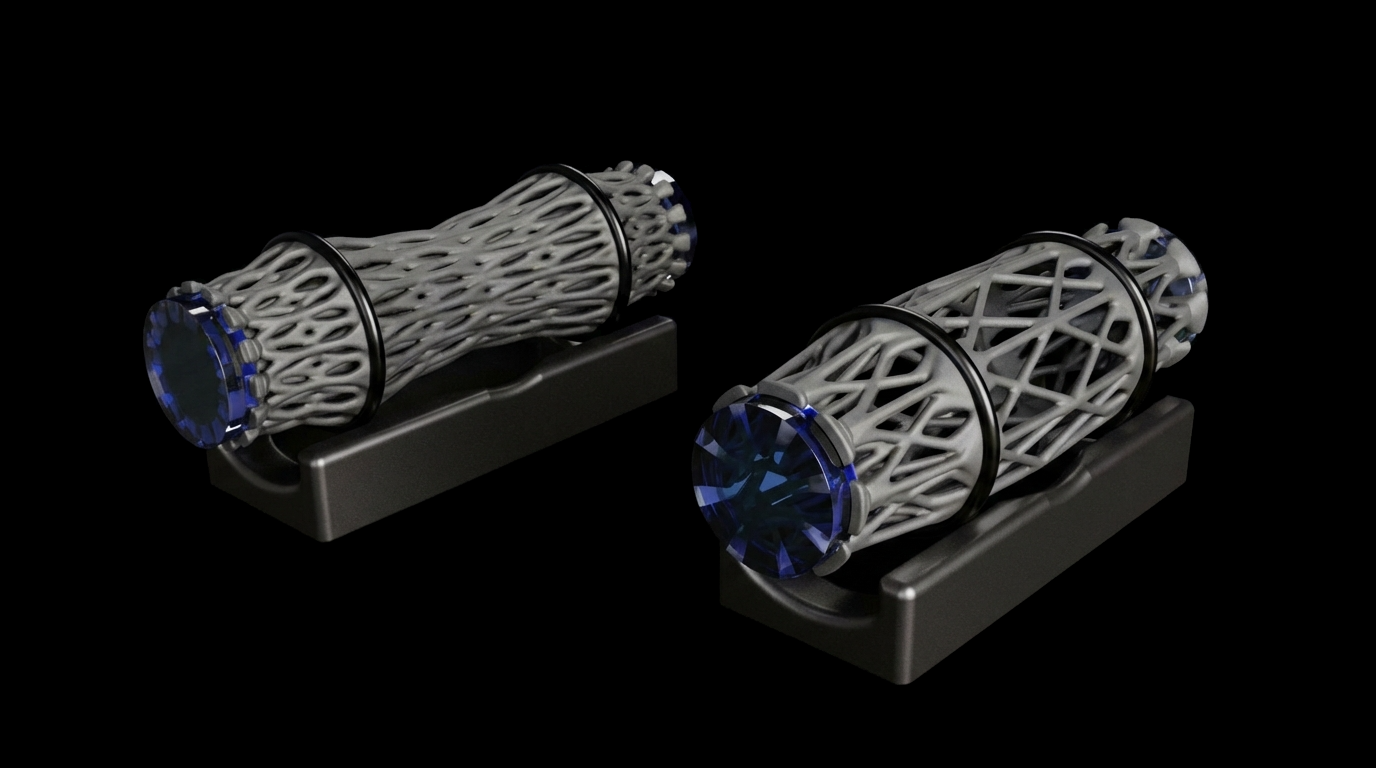

At Metamorphic, we help forward-thinking organisations harness the real potential of additive manufacturing. We offer bespoke design consultancy that integrates computational design, simulation, and advanced AM insight to unlock the kind of geometries software alone can’t reach.

Since 2021, we’ve supported R&D programmes worth over £8M across sectors like Quantum Technologies, Fusion Energy, Telecommunications, Medical Devices, and Wearables. Whether the challenge is creating plasma-facing components for nuclear fusion reactors or UHV chambers for quantum sensing, we always start with engineering intent and, where required, finish with production-ready outcomes.

We don’t use tools to replace engineering. We use them to amplify it.

We have worked with